Rapid prototyping: FDM vs SLA vs SLS (complete guide 2025/26)

If you've ever had an idea in your head and wanted to turn it into a real object in a matter of hours, you know the magic of rapid prototyping. 3D printing has democratised access to tools that were previously only available to large companies, and today you can materialise a design on your desk with a reasonable investment. But choosing the right technology makes the difference between a working prototype and a part that doesn't live up to your expectations.

In this guide we compare the three most relevant 3D printing technologies for rapid prototyping: FDM (Fused Deposition Modeling), SLA (Stereolithography) and SLS (Selective Laser Sintering). You will understand when to use each, what materials they accept, what level of detail they achieve and how much they really cost. If you are exploring product design as a future career, UDIT's Degree in Product Design and Development gives you access to these technologies from the first year, with real projects and ongoing technical mentoring.

What is rapid prototyping and why does it matter?

Rapid prototyping is the process of manufacturing a physical representation of your design in the shortest possible time. We are not talking about mass production, but rapid iteration: you design, print, test, tweak and print again. This compressed cycle allows you to validate ideas, catch design errors and communicate your concept clearly before investing in expensive moulds or tooling.

Until a decade ago, making a working prototype could take weeks and thousands of euros. Today, with a 3D printer and the right digital file, you can have your part in hours and for a cost that rarely exceeds €50. This speed and accessibility has transformed product design, medical device development, mechanical engineering and industrial design.

The three technologies that will dominate rapid prototyping in 2025

Each technology has its internal logic, advantages and limitations. There is no universal "best" option: there is the best option for your specific project. Let's break it down.

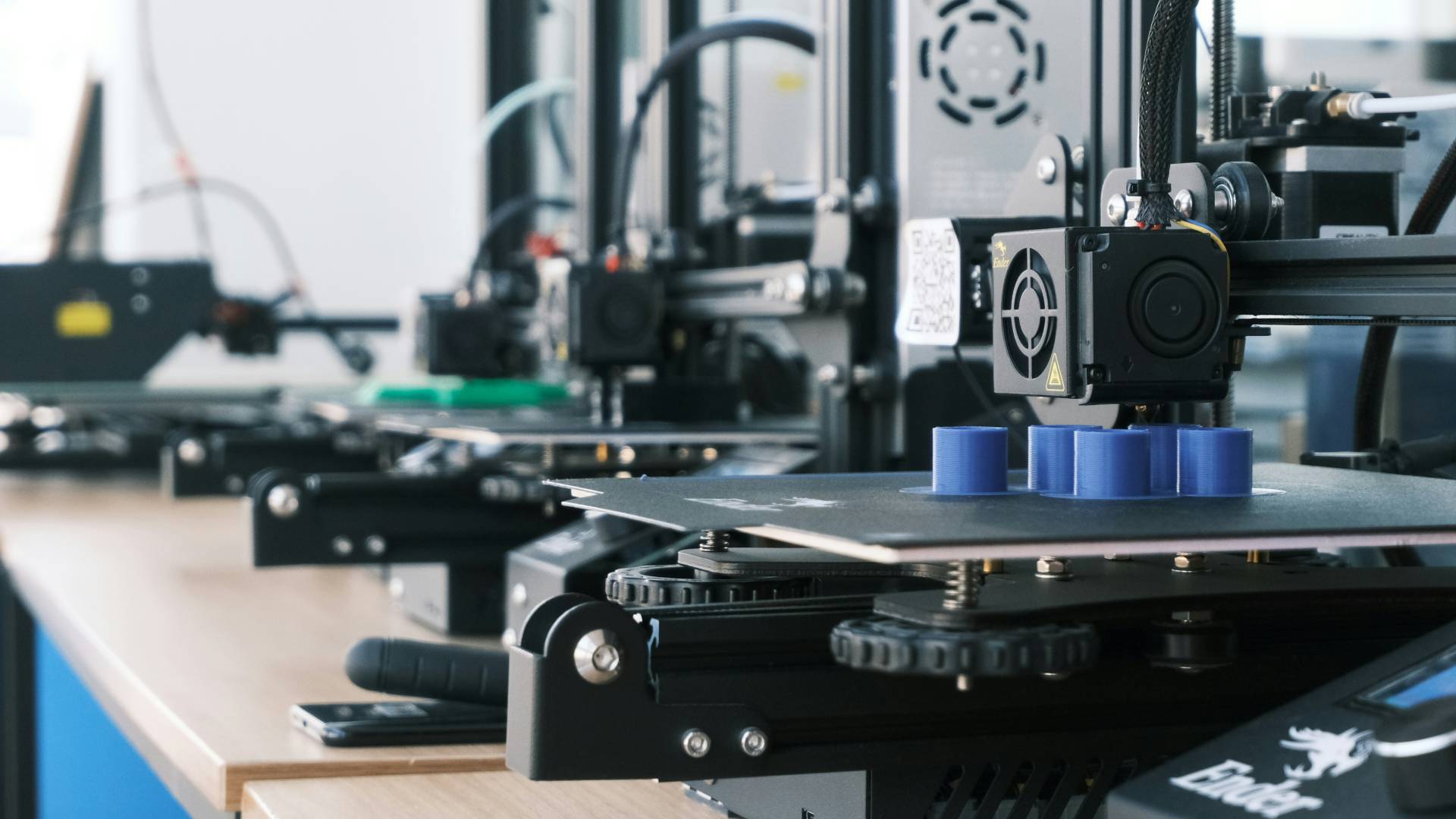

FDM (FusedDepositionModeling): the most accessible and versatile option

How does it work?

FDM printing deposits molten plastic filament layer by layer, like an ultra-precise hot glue gun. An extruder head heats the filament (usually PLA, PETG or ABS) until it becomes malleable, deposits it in the pattern of your design and allows it to cool to solidify. Then repeat the process on the next layer until the part is complete.

Advantages of FDM

- Affordability: You can start with printers from 200 € and materials are cheap (between 15 € and 30 € per kilo of filament).

- Variety of materials: PLA (biodegradable, easy to print), PETG (resistant, more flexible), ABS (durable, heat resistant), TPU (flexible like rubber), nylon (abrasion resistant), composites with carbon fibre or wood.

- Ease of use: The learning curve is gentle. In an afternoon you can be printing functional parts.

- Easy repair and maintenance: Spare parts are affordable and online communities are full of tutorials.

Limitations of FDM

- Visible surface finish: Layers are noticeable to the touch and eye. If you need a polished-looking part, you'll need to sand and paint.

- Limited resolution: Layer height is typically between 0.1 mm and 0.3 mm. For very fine details (such as small textures, delicate hinges or complex geometries), FDM falls short.

- Anisotropy: Parts are weakest in the Z-axis (perpendicular to the layers). If you apply force in that direction, they can break by delamination.

- Visible supports: Geometries with overhangs need supports that leave marks on the part.

When to use FDM?

- Functional prototypes that do not require extreme detail.

- Mechanical parts for assembly testing.

- Rapid iterations where cost and speed are priorities.

- Educational or personal projects where finish is not critical.

Real world example: Imagine you are designing a housing for an electronic device. With FDM you can print iterative versions to test component fit, validate screw holes and check ergonomics, all in less than 24 hours and for less than €5 per iteration.

SLA (Stereolithography): precision and professional finish

How does it work?

SLA printing uses a UV laser to solidify liquid resin layer by layer. The part is built up submerged in a tank of resin, and the laser draws each layer with millimetre precision. After each layer, the build platform rises slightly and the process is repeated. Once finished, the part is washed in isopropyl alcohol to remove excess resin and cured with UV light to achieve maximum strength.

Advantages of SLA

- Exceptional resolution: Layers down to 25 microns (0.025 mm). Ideal for fine details, textures, small threads and organic geometries.

- Smooth surface finish: Parts come out with a near-polished finish, without the visible layer lines of FDM.

- Isotropy: Parts have uniform mechanical properties in all directions.

- Variety of speciality resins: Transparent, flexible, heat-resistant, biocompatible (for medical use) or castable (for jewellery and dentistry) resins.

Limitations of SLA

- Higher cost: Quality SLA printers start at around €400 - €500, and resins cost between €40 and €150 per litre (depending on specific properties).

- Mandatory post-processing: Washing, curing and removing supports takes time and requires a dedicated space with ventilation.

- Fragility of some resins: Standard resins can be brittle. If you need parts that can withstand impact, you will have to choose specific (more expensive) resins.

- Shelf life of resins: Resin can degrade over time if not stored correctly.

When to use SLA?

- Prototypes that require high visual and dimensional fidelity.

- Parts for presentations to customers or investors.

- Architectural models, models, figures or jewellery.

- Functional prototypes with fine details (small hinges, precise fittings, textures).

Real-world example: You are designing a prototype of a custom in-ear headset. With SLA you can capture the organic geometry of the ear canal with a precision that guarantees a perfect fit, something impossible with FDM. In addition, the smooth finish allows you to test the product directly without extensive post-processing.

SLS (Selective Laser Sintering): industrial strength without brackets

How does it work?

SLS printing uses a high-power laser to fuse powder particles (usually nylon or polyamide) layer by layer. The process takes place in a preheated chamber filled with powder, and the laser sinters (fuses without completely melting) the particles according to the pattern of the design. The unsintered powder acts as a natural support, which means you can print complex geometries without the need for additional structures.

Advantages of SLS

- No need for supports: The unsintered powder supports the part during printing, allowing geometries impossible with other technologies.

- Superior mechanical strength: Parts are strong, durable and functional. You can use them directly in engineering applications.

- Complete isotropy: Uniform mechanical properties in all directions.

- Design freedom: Interlocking geometries, internal channels, extreme overhangs... anything is possible.

- Multiple part production in a single print: You can fill the build chamber with dozens of small parts and make maximum use of space.

Limitations of SLS

- High cost: Professional SLS printers start at around €5,000 - €10,000 (and industrial printers are over €100,000). Powder costs between €60 and €100 per kilo.

- Rough surface finish: Parts have a grainy texture that requires post-processing if you need a smooth finish (polishing, vibrating, painting).

- Operational complexity: Requires precise temperature control, adequate ventilation and thorough cleaning between prints.

- Less accessible for personal use: Because of cost and complexity, SLS is often reserved for educational environments, design labs or professional printing services.

When to use SLS?

- Functional prototypes that must withstand real mechanical load.

- Short-run end-use parts (100-1000 units).

- Complex geometries with integrated assemblies or internal channels.

- Design validation before plastic injection or CNC machining.

Real world example: You are developing a custom drone and need to test structural parts before investing in moulds. With SLS you can print the arms, motor mounts and electronics housings with nylon, test them in real flight and validate their resistance to vibration and impact. If they work, you have the confidence to move to production.

Direct comparison: FDM vs SLA vs SLS

To help you decide, here's a table summarising the key differences:

Criteri a | FD M | SL A | SL S |

Resolutio n | Medium (0.1 - 0.3 mm ) | High (0.025 - 0.1 mm ) | Medium-High (0.1 mm ) |

Surface finish | Visible coating lines | Smooth, almost polished | rough, grainy |

Mechanical resistance | medium, anisotropic | medium, isotropic (depending on resin ) | high, isotropic |

Support required | Yes | Yes | No |

Variety of materials | High (PLA, PETG, ABS, TPU, nylon, composites ) | High (standard resins, flexible, biocompatible, castable ) | Medium (nylon, polyamide, TPU ) |

Input cost (printer ) | 200 € - 1.000 € | 400 € - 3.000 € | 5.000 € - 100.000 € + |

Cost of materials | Low (15 € - 30 €/kg ) | Medium (40 € - 150 €/L ) | High (60 € - 100 €/kg ) |

Post-processin g | Optional (sanding, painting ) | Mandatory (washing, curing ) | Optional (polishing, painting ) |

Printing speed | Medium (3-12 hours ) | Fast (1-8 hours ) | Medium-Slow (8-24 hours ) |

Best for... | Low-cost functional prototypes, rapid iteration | High visual fidelity, fine detail, presentations | Robust functional parts, complex geometries, engineering validation |

How to choose the right technology for your project

The decision is not technical but strategic. Ask yourself these questions before you start:

1. What level of detail do you need?

- Low-medium: FDM is sufficient.

- High: SLA is your choice.

- Medium with mechanical strength: SLS.

2. What are you going to use the prototype for?

- Assembly or fit testing: FDM.

- Visual presentation or ergonomics testing: SLA.

- Functional validation under load: SLS.

3. How much can you spend?

- Tight budget: FDM.

- Medium budget: SLA.

- Large budget or lab access: SLS.

4. What mechanical properties do you need?

- Non-critical: FDM or SLA (with standard resin).�

- Medium strength: FDM with PETG or nylon.

- High strength: SLS with nylon or SLA with technical resins.

5. Do you have access to equipment and space for post-processing?

- No: FDM is the cleanest option.

- Yes, with ventilation: SLA is viable.

- Yes, in an equipped lab: SLS is possible.

The role of rapid prototyping in professional product design

In UDIT's Degree in Product Design and Development, rapid prototyping is not an optional subject: it is a transversal tool that you use from the first year. You learn to choose the right technology according to the phase of the project, the budget and the validation objectives. You work with all three technologies (FDM, SLA and SLS) on real projects, and you understand not only how to print, but what to print, when and why.

Professional product design requires technical judgement. It's not enough to know how to use a 3D printer; you have to understand tolerances, material properties, the limitations of each technology and the complete flow from sketch to final part. That integrated view is what makes you a competent product designer, not just a software user.

Common mistakes when getting started with rapid prototyping

1. Choosing technology out of fashion, not necessity .

Many people start with SLA because it "looks professional", but end up frustrated with post-processing. Start with FDM if you are learning. It's more forgiving, cheaper and allows you to make mistakes without going broke.

2. Ignore dimensional tolerances.

Every technology has its margin of error. FDM can deviate up to ±0.3 mm; SLA up to ±0.1 mm; SLS up to ±0.15 mm. If you design a socket with tolerances of 0.05 mm and print it in FDM, it won't fit. Learn to compensate in the design.

3. Not optimising the design for the chosen technology

A design intended for plastic injection moulding does not work the same in 3D printing. Overhangs, wall thicknesses, demoulding angles... everything changes. Adapt your design to the technology, not the other way around.

4. Underestimating post-processing

A freshly printed piece is rarely the final piece. Sanding, painting, curing, assembly... it all takes time. Include it in your planning.

5. Not documenting iterations

Every prototype is a learning experience. If you don't document what worked and what didn't, you will repeat mistakes. Keep track of print parameters, materials, timing and results.

Conclusion

Rapid prototyping is not just a tool; it's a mindset. It allows you to fail fast, learn from each iteration and arrive at robust solutions in a fraction of the time required by traditional methods. FDM gives you accessibility and versatility to iterate endlessly. SLA gives you precision and finish for presentation prototypes. SLS gives you resilience and geometric freedom to validate complex designs under real load.

There is no perfect technology, but there is the perfect technology for your project. Learn to choose wisely, master all three options and you will have a huge competitive advantage in the product design market.

If your goal is to become a professional product designer with real technical mastery, UDIT's Degree in Product Design and Development gives you access to all three technologies from the first year, with applied projects, ongoing technical mentoring and an execution-focused approach. You don't just learn theory; you make, test, iterate and deliver working prototypes that solve real problems.

The future of product design is in the hands of those who know how to realise ideas with speed, precision and judgement. Rapid prototyping is your starting point - are you ready to get started?

Frequently asked questions

1. What is the cheapest 3D printing technology to get started with rapid prototyping?

FDM is the most affordable option, you can start with a decent printer for €200 - €400 and the material costs between €15 and €30 per kilo. It is ideal for learning the basics of rapid prototyping without a high initial investment. If you are exploring product design as a career, UDIT's Degree in Product Design and Development gives you access to all three technologies from the start, allowing you to choose the best tool for each project without financial constraints.

2. Which technology should I use if I need prototypes with very fine details?

SLA is the best choice for high resolution and smooth finish. It achieves layers down to 25 microns (0.025 mm), making it perfect for architectural models, medical models, jewellery or any prototype where visual detail is critical. Parts come out with a near polished finish, although post-processing (washing in isopropyl alcohol and UV curing) is required.

3. Can I use 3D printed prototypes for actual functional testing?

Yes, but it depends on the technology and material. With FDM, you can use PETG or nylon for functional parts with medium strength. With SLA, there are technical resins (such as heat-resistant or impact-resistant resins) that allow functional testing, although they tend to be more expensive. With SLS, nylon parts have mechanical properties comparable to injection moulded parts, making them ideal for demanding functional validation. In UDIT's Degree in Product Design and Development, you learn how to select the right material and technology for the type of validation you need.

4. Which technology does not need printing media?

Only SLS prints without substrates. The unsintered powder acts as a natural support during printing, allowing complex geometries, extreme overhangs and integrated assemblies without additional structures. Both FDM and SLA require supports for overhangs and hanging geometries, and these supports leave marks on the part that need to be removed in post-processing.

5. How long does it take to print a prototype with each technology?

The printing time depends on the size of the part, the resolution chosen and the complexity of the geometry:

- FDM: Between 3 and 12 hours for medium-sized parts (10 x 10 x 10 x 10 cm) with standard resolution (0.2 mm).

- SLA: 1 to 8 hours for similar parts, although post-processing (washing and curing) adds an additional 30-60 minutes.

- SLS: 8-24 hours, but you can print multiple parts in the same session, which optimises time if you need multiple units.

Speed is not everything: the important thing is to choose the technology that gives you the right result in the time you need.