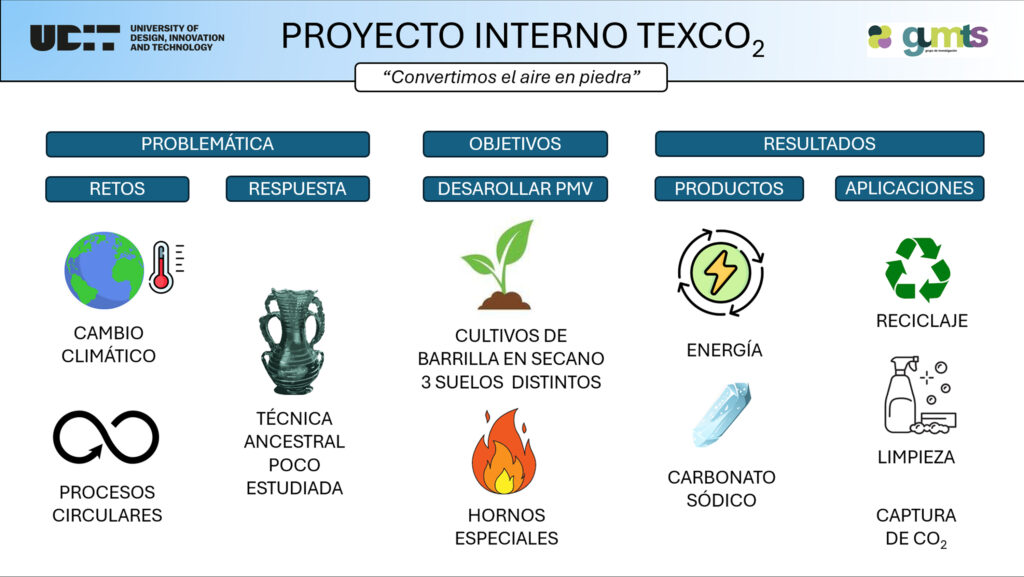

Biomass cells solidifying CO2 in textile sustainability processes (TEXCO2)

Project title: Células de biomasa que solidifican CO2 en procesos de sostenibilidad textil (TEXCO2) / Biomass cells solidifying CO2 in textile sustainability processes.

Code: INC-UDIT-2025-PRO24

PI Project: Phd. David Antonio Rosas Espín (david.rosas@udit.es)

objectives

Can we turn air into stone?

- Cultivate fine barilla in areas with a historical tradition.

- Obtain sodium carbonate after burning the barrils in newly designed kilns, as a Minimum Viable Product, improving ancestral techniques.

- Use soda in textile circularity processes, ecological cleaning products and artistic glass.

Methodology

Following ancient treaties, we will cultivate fine barrilla in different terrains of Huéscar and Castril (Granada), belonging to the UNESCO Geopark of Granada.

Panoramic view from plot 3 (Parque Natural de la Sierra de Castril)

The fine barilla, which is highly photosynthetic (C4), extracts salts from the soil and, when burnt under specific conditions, generates sodium carbonate, which was used to make beautiful glass.

Both the cultivation of fine barilla and the profession of the barrillero have fallen into oblivion, and we only have a descriptive knowledge of these processes.

Therefore, in a first phase, we will use precision agriculture (IoT and drones) to optimise the methods of cultivation of fine barilla.

In a second phase, we will develop special ovens in the UDIT FabLabs as a Minimum Viable Product. These furnaces, designed to withstand the very high temperatures and corrosion of the barilla, will optimise the production of soda, energy and CO2 capture, literally turning air into stone.

Panoramic view of plot 2 (Cañada María-Huéscar) with Sierra Nevada in the background.

practical applications

First phase: We introduce a rainfed crop suitable for water-scarce areas. This crop cleans the soil of salts, combats desertification and global warming by capturing CO2.

Second phase: The dried plants are burned in special mobile ovens, generating energy and soda ash in a second CO2 capture process. The surplus energy and soda ash have versatile applications in circular processes for the production of soaps, biofuels and degreasing agents, as well as in the textile, ceramics, metallurgy and glass industries.

Plot 1 in fallow land with Mount Perico Ruíz in the background (Huéscar-Granada).

innovation and competitiveness

These combined cycles generate biomass energy and solidify CO2 from the air.

They are useful in versatile circular processes with a negative carbon footprint, saving water, cleaning soils of salts and pollutants.

They would be an interesting alternative in rotations of other rainfed crops to stimulate local industry in rural areas.

Improvements to traditional processes through cutting-edge technologies offer a sustainable alternative for industrial decarbonisation.