Transforming industry through digital manufacturing

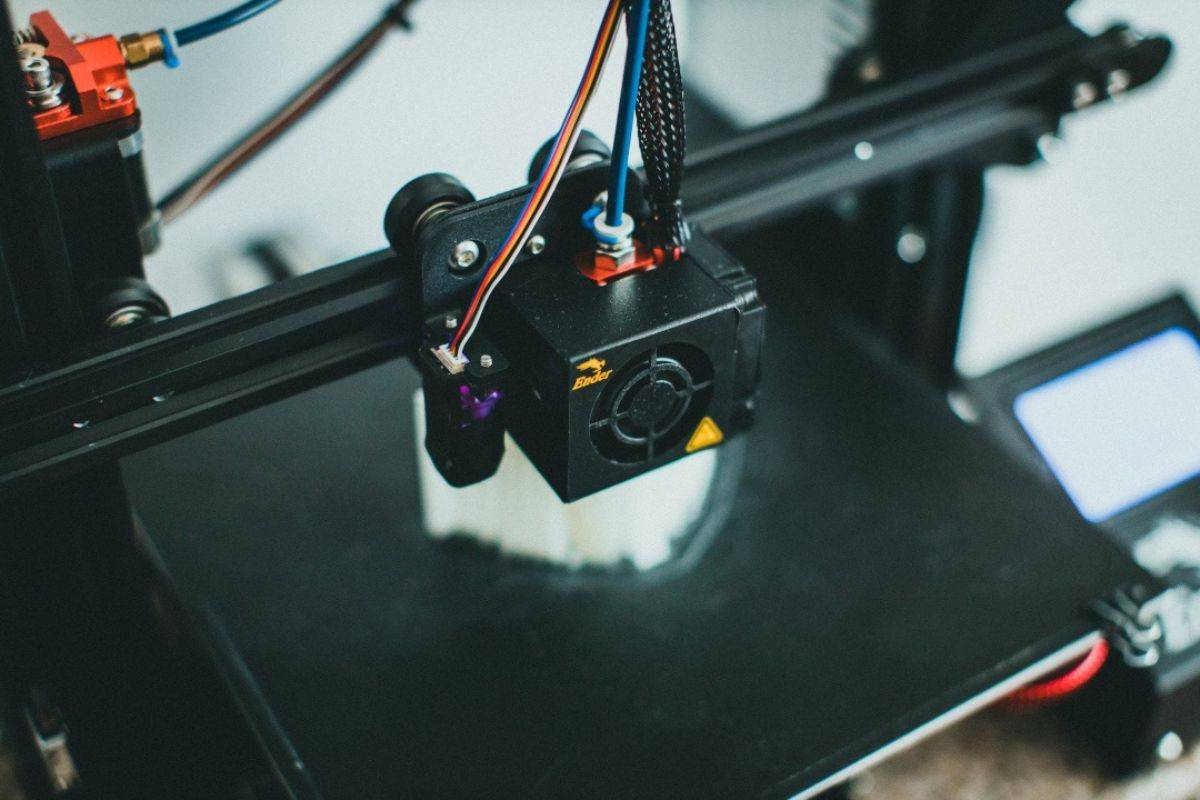

Digital fabrication, and especially 3D printing, have revolutionised the way objects are designed, developed and produced, positively impacting product design. These technologies have redefined the boundaries of creativity and production, but what can they bring to Product Design?

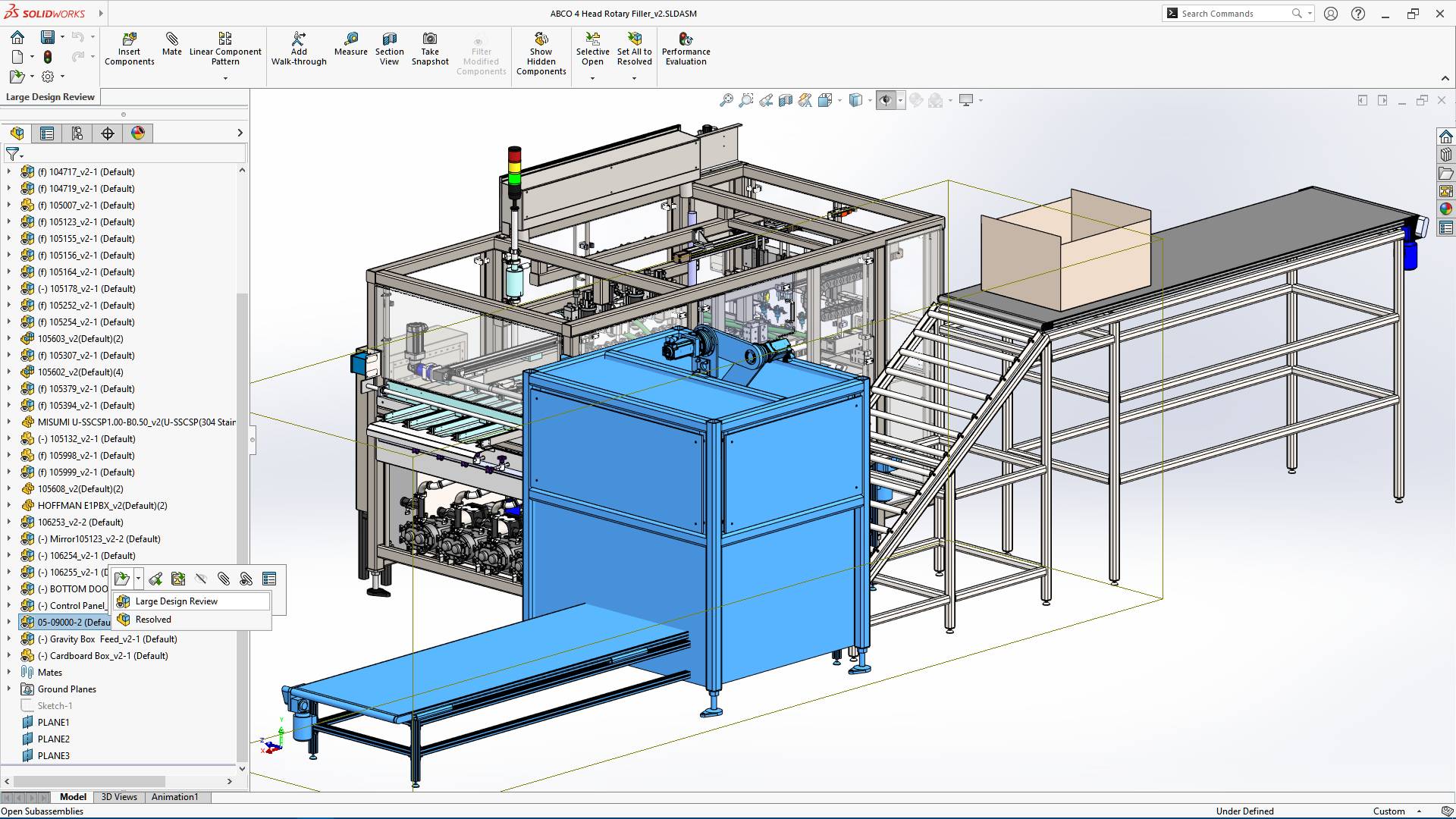

Digital manufacturing encompasses a broad spectrum of technologies, from 3D printing to modelling, process automation through software and specific machinery, which aim to create a product or part through the design and modelling of objects. This set of digital tools provides greater precision, efficiency and versatility in the production process.

Advantages of digital manufacturing

The importance of digital manufacturing lies in three key elements:

The first is the ability to customise, both existing products and to create unique, personalised items, allowing products to be tailored to specific needs.

The second is cost reduction and more efficient production: these technologies require fewer tools (fewer pieces of equipment to manufacture a product) and, above all, reduce material waste.

Third, and perhaps most importantly, they boost creativity and innovation by allowing experimentation with complex designs and shapes that were unthinkable in digital manufacturing.

Designing medical prosthetics: the potential of these advances

Digital fabrication and 3D printing have positively impacted multiple industries, including medicine. The design and manufacture of prostheses used to involve complex processes and long lead times, which have disappeared with new manufacturing technologies.

Today, custom-made prostheses can be produced in a matter of days and to the exact measurements required. Digital manufacturing has also made it possible to reduce costs and improve the comfort and functionality of the designs. So much customisation is possible that precise anatomical models can be created.

For example, in surgery , exact replicas of organs or affected areas in the body can be made, allowing surgeons to practice procedures before the actual operation.

There are many more examples like this. Technological innovations are being integrated into all industries, promoting production efficiency and improving people's quality of life.

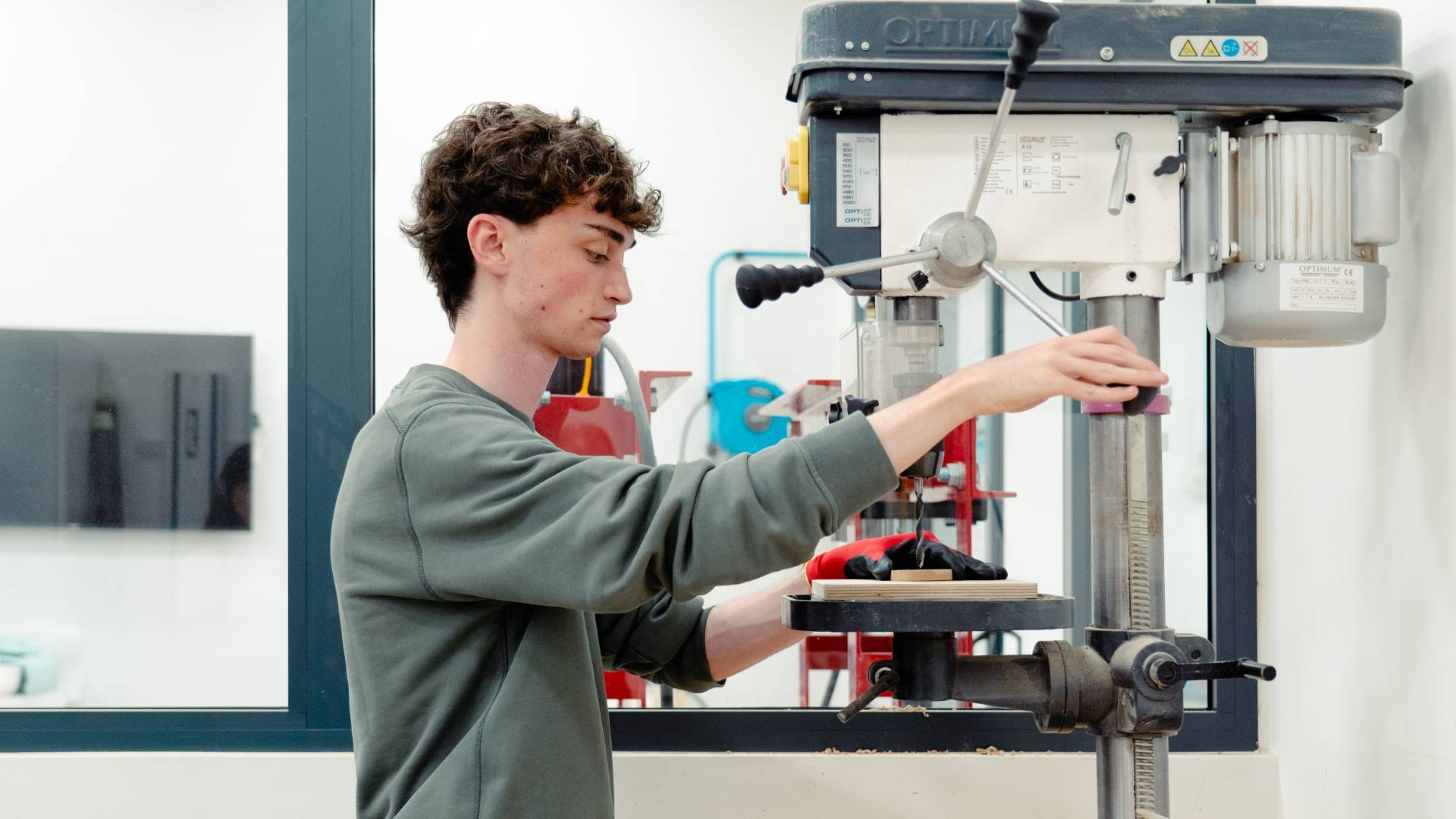

UDIT: State-of-the-art Fab Lab

At UDIT we have the most cutting-edge equipment and facilities, including a state-of-the-art digital manufacturing and research laboratory . In July 2017, it was internationally approved and included in the Fab Foundation's Fab Labs network, an organisation that originated at M.I.T. (Massachusetts Institute of Technology) and currently has more than 1,000 digital manufacturing laboratories around the world.