What is a CNC milling machine for: Uses in the Product Design Degree?

Product design is a field that combines creativity and technology to create functional, aesthetic and sustainable objects. Within this industry, the tools used are key to transform ideas into tangible products. One of the most important technologies in this field is the CNC milling machine, a machine that has revolutionised the manufacture of components and prototypes thanks to its precision and versatility.

In this article, we will explore what a CNC milling machine is, how it works and why it is one of the fundamental pieces of equipment used by students on UDIT's Degree in Product Design to carry out their projects.

What is a CNC milling machine?

A CNC milling machine is a computer-controlled machine used to machine parts by means of the rotary movement of a cutting tool. The acronym CNC stands for Computer Numerical Control, indicating that the operation of the milling machine is based on pre-programmed commands rather than being manually manipulated.

Unlike conventional milling machines, which require the direct intervention of an operator to set parameters and perform movements, CNC milling machines work autonomously, ensuring an exceptional level of accuracy and repeatability. This is especially valuable in the product design discipline, where accuracy of detail and finish can make the difference between the success and failure of a project.

How does a CNC milling machine work?

The operation of a CNC milling machine is based on three main elements:

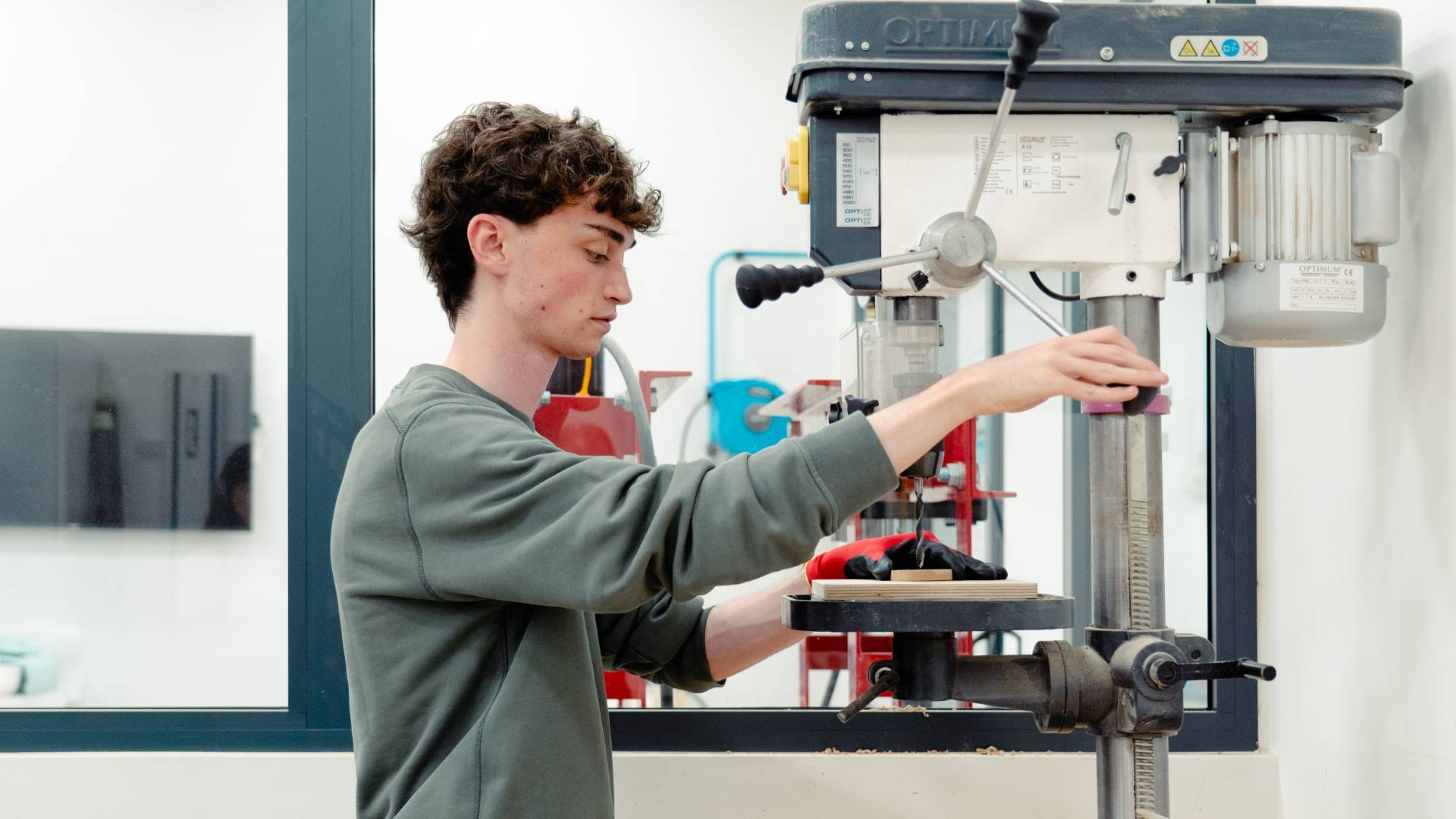

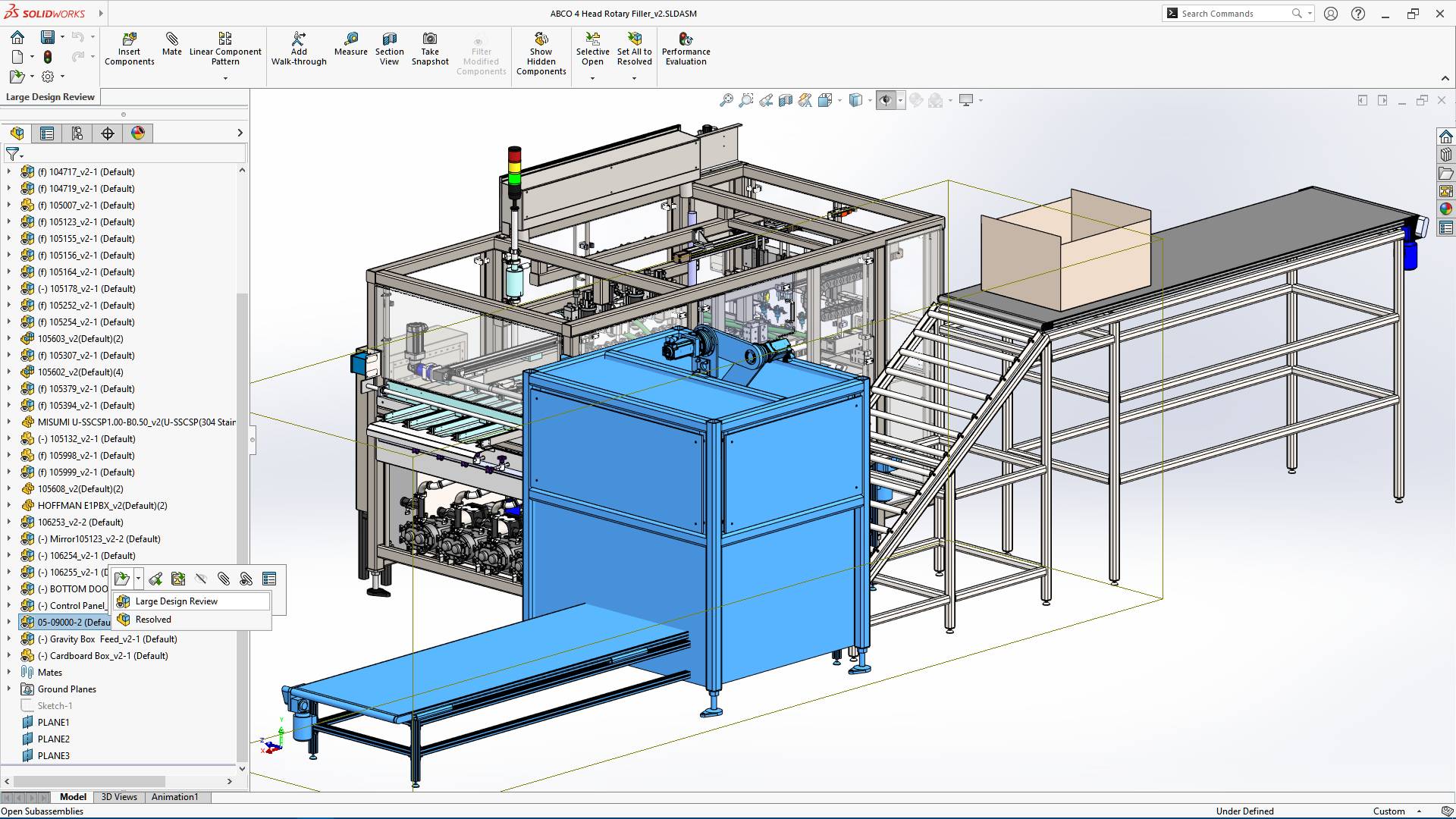

Computer Aided Design (CAD): The first step is to create a digital model in design software such as AutoCAD, SolidWorks or Fusion 360. This model contains the exact specifications of the product to be manufactured.

During the degree, students of the Degree in Product Design learn to use these digital 2D and 3D modelling tools, which are essential for the world of work. In fact, UDIT is a SolidWorks partner centre, which offers you the chance to become certified as an expert in this tool.

👇 What is SolidWorks and what is it used for?

Computer Aided Manufacturing (CAM): Once the design is ready, CAM software is used to convert the model into a set of instructions that the milling machine can interpret. These instructions, called G-code, detail movements, speeds and depths of cut.

Machining: The CNC milling machine executes the G-code, moving the cutting tool precisely over the material to shape the product.

Uses of CNC milling in product design

In the field of product design, CNC milling machines play a crucial role in various stages of the creative and manufacturing process. Some of their most relevant uses are highlighted below:

- Rapid prototyping

CNC milling machines allow designers to quickly transform a digital model into a physical prototype. This is essential for testing concepts, evaluating functionality and making adjustments prior to mass production.

- Mould making

Many products require moulds for production. CNC milling machines are ideal for making precise moulds, whether for plastic injection moulding, metal casting or thermoforming.

- Custom part production

The design of bespoke products, such as exclusive furniture or luxury components, benefits greatly from the precision of CNC milling machines.

- Mass production

Although often associated with customisation, CNC milling machines are also effective for small and medium batch production, especially in projects where multiple identical components are required.

- Details

CNC routers allow complex patterns to be engraved, textured and decorative details to be worked with millimetre precision.

Advantages of using CNC milling machines

The use of CNC milling machines offers multiple benefits in product design such as precision, efficiency, error reduction, versatility and reproducibility.

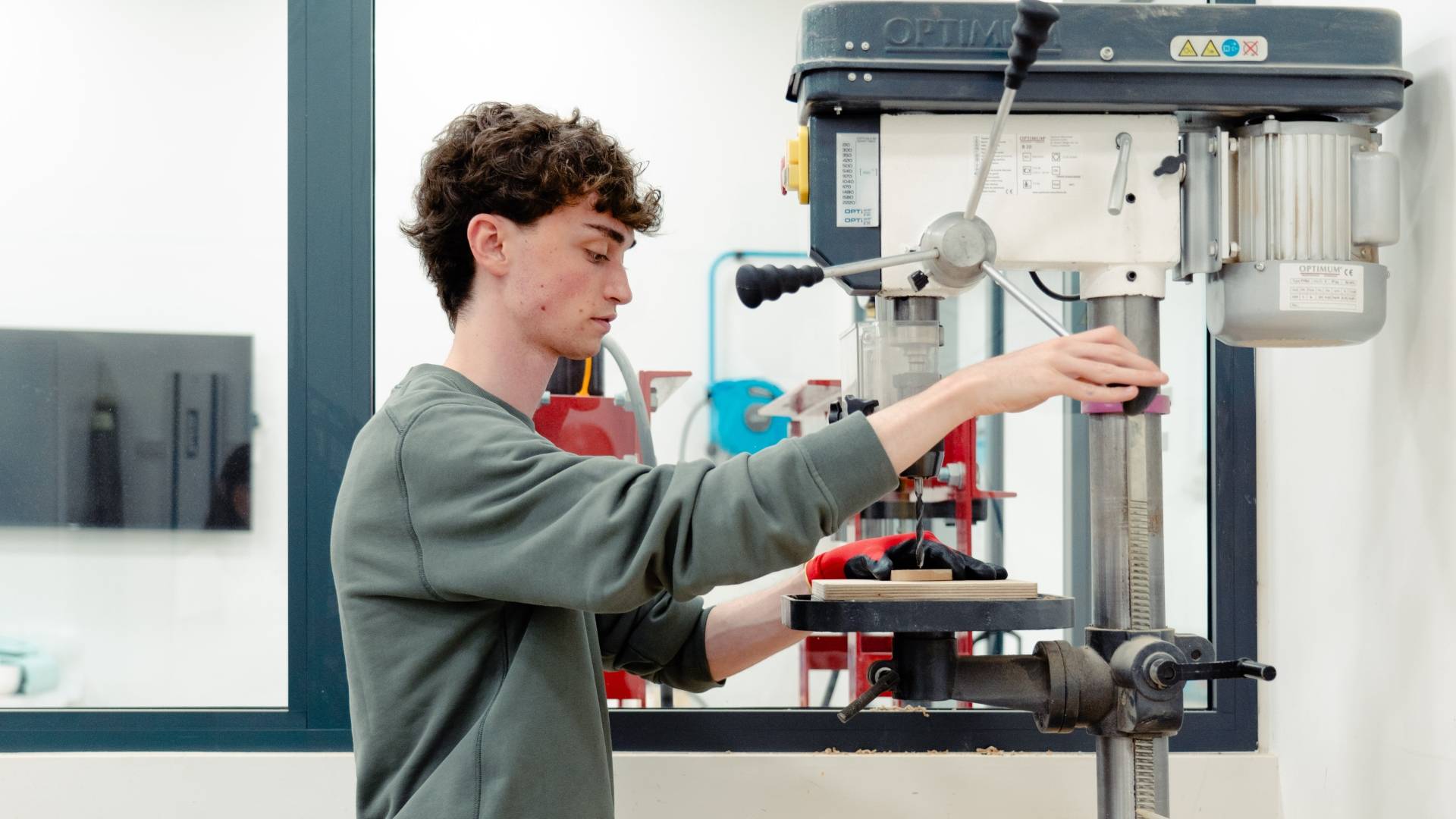

FAB LAB UDIT: the ultimate manufacturing laboratory

The Degree in Product Design is the perfect intersection between Industrial Engineering, EcoDesign and Technological Innovation, a discipline that brings together art, science and technology.

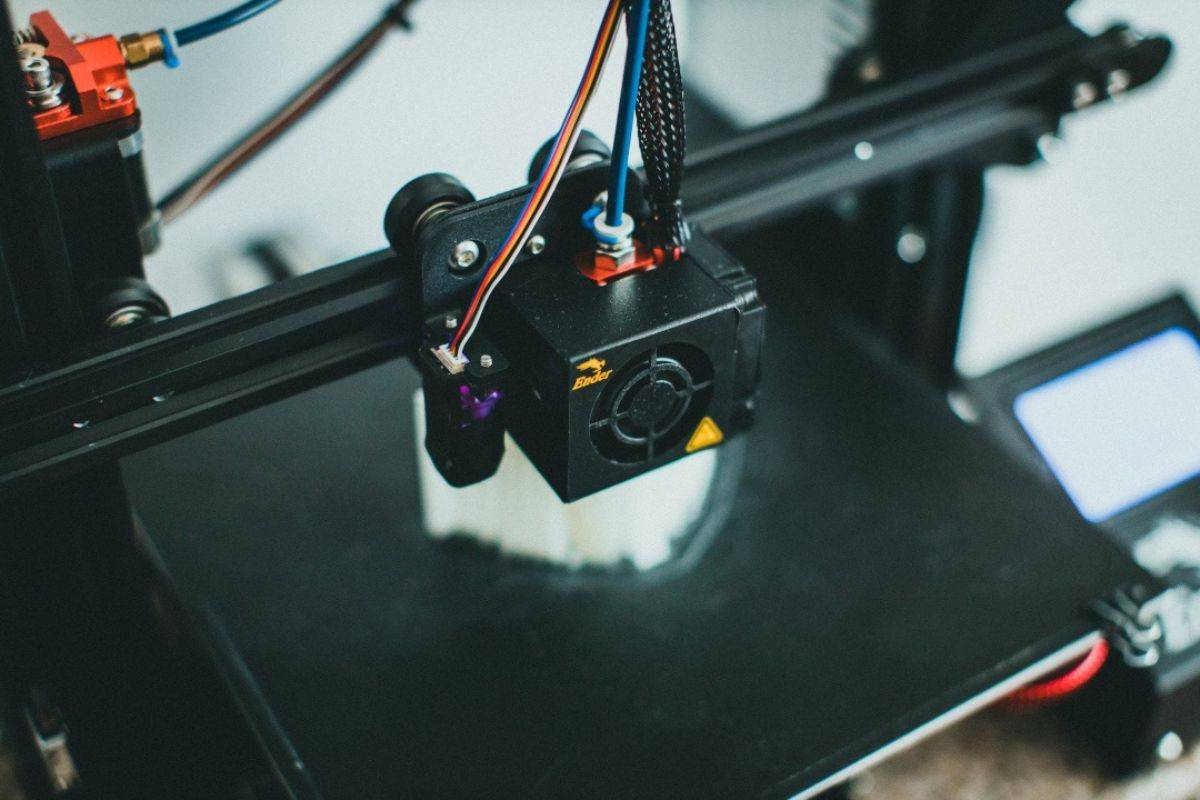

During the four courses, you will work on models and prototypes on technical aspects such as mechanics, kinematics or energy, materials and three-dimensional representation of objects and the manufacture of products with ergonomics and accessibility in mind. To do so, you will use the equipment and spaces available in the university's Fab Lab, where you will find laser and water cutters, 3D printers, CNC milling machines, etc.

Our state-of-the-art digital fabrication and research lab was internationally accredited in July 2017 and included in the Fab Labs network of the Fab Foundation, an organisation that was born at M.I.T (Massachusetts Institute of Technology) and currently has more than 1,000 digital fabrication labs around the world.

Are you a creative person with an inquiring mind and a passion for art, science and technology? The Degree in Product Design is the perfect choice for you. Discover this degree and why UDIT is the right place for you.