What is SolidWorks and what is it used for?

SolidWorks is acomputer-aided design (CAD)software widely used in mechanical engineering, industrial design and product development. Developed by Dassault Systèmes, SolidWorks stands out for its ability to create accurate and detailed three-dimensional models, allowing designers and engineers to visualise, simulate and modify their creations before moving to the manufacturing stage.

Since its launch in 1995, SolidWorks has revolutionised the way products are conceived and developed, integrating advanced modelling, simulation and data management tools. The software is not only an essential tool for engineers and designers, but also essential for companies looking to optimise their product development process and reduce costs.

4 SolidWorks features

SolidWorks offers features that make it an indispensable tool for product design. Here are four of the main features of this 2D and 3D mechanical modelling software .

1. Parametric Modelling

Parametric modelling is one of SolidWorks' core strengths. This approach allows designers to create 3D models based on parameters, such as dimensions, constraints and relationships between different parts of the design. This means that any change in a parameter is automatically reflected throughout the model, making it easy to modify and optimise the design.

For example, if a designer needs to change the length of a part, they can simply adjust the corresponding parameter, and the model will automatically update to reflect this change. This is especially useful in complex projects where quick adjustments need to be made without losing design integrity.

2. Simulation and Analysis

SolidWorks integrates powerful simulation tools that allow users to perform structural, thermal, and fluid analysis directly within the design environment. These simulation tools are crucial for validating a product's performance under different conditions prior to manufacturing.

For example, an engineer can use SolidWorks to simulate how a part will respond to a given load or how a product will behave under extreme temperature conditions. This type of analysis helps identify potential failures or areas for improvement, reducing the need for costly physical prototypes and testing.

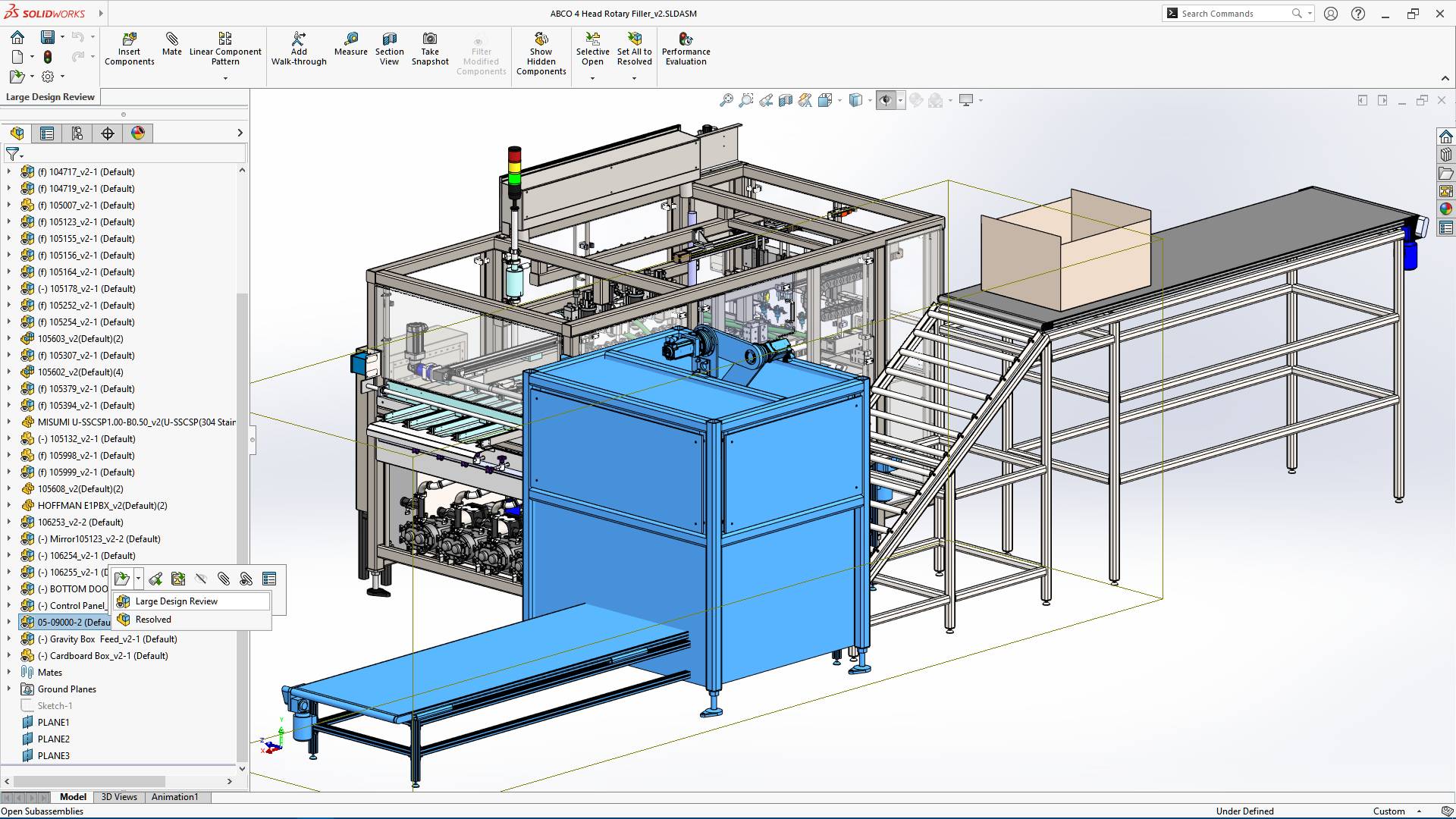

3. Complex assemblies

SolidWorks is capable of handling complex assemblies, which can include thousands of individual parts. This is critical in large-scale design projects, such as industrial machinery, automobiles or electronic equipment.

The software allows designers to virtually assemble and disassemble parts, check their interaction, and ensure that all parts fit together correctly. In addition, SolidWorks provides tools to detect interferences and collisions within the assembly, which helps avoid problems during manufacturing.

4. Product Data Management (PDM)

SolidWorks also includes product data management (PDM) tools, which are essential for handling large volumes of information generated during the design process. PDM enables design teams to efficiently store, manage, and share data, ensuring that all team members are working with the most current version of the design.

This functionality is useful in collaborative environments, where designers and engineers may be working on different aspects of the same project at the same time. SolidWorks PDM helps avoid version errors and makes it easier to track changes throughout the product lifecycle.

Uses of SolidWorks in Product Design

SolidWorks is used in many industries and applications because of its versatility and power. Some of the most common uses of SolidWorks in product design are described below:

1. industrial machinery and equipment design 2.

One of the most common applications of SolidWorks is in the design of industrial machinery and equipment. Engineers use the software to create detailed models of machines, tools, and production systems. SolidWorks allows designers to visualise each component, ensure that all parts fit together correctly, and perform simulations to verify equipment performance under different operating conditions.

For example, a company that manufactures agricultural machinery might use SolidWorks to design and test a new tractor model. The software allows each component, from the chassis to the internal mechanisms, to be modelled and simulates how the machine will perform in the field.

2. Consumer product development

SolidWorks is also widely used in the development of consumer products, such as home appliances, electronic devices, furniture and toys. Designers can create accurate 3D models of products, perform simulations to test durability and performance, and optimise the design to improve ergonomics and aesthetics.

For example, a designer working on the development of a new mobile phone can use SolidWorks to model the device, ensure that all internal components fit within the design, and simulate the product's behaviour in different scenarios, such as drops or exposure to liquids.

3. Automotive and transportation design

The automotive industry is another area where SolidWorks has a significant impact. Automotive engineers use the software to design and optimise every aspect of a vehicle, from the chassis and body to the engine and suspension systems. SolidWorks allows them to perform aerodynamic simulations, analyse the vehicle's behaviour in different driving conditions and ensure that all parts of the car are assembled correctly.

For example, during the design of a new car, engineers can use SolidWorks to model the chassis, perform virtual crash tests, and optimise the design to improve fuel efficiency and vehicle safety.

4. Medical Product Design

SolidWorks is also used in the medical industry to design medical devices, prosthetics, and surgical equipment. The ability to create accurate models and perform simulations is especially important in this field, where accuracy and reliability are crucial.

For example, a biomedical engineer might use SolidWorks to design a new hip prosthesis. The software allows the prosthesis to be modelled, simulate how it will behave under the weight of the human body and adjust the design to ensure a perfect fit and optimal performance.

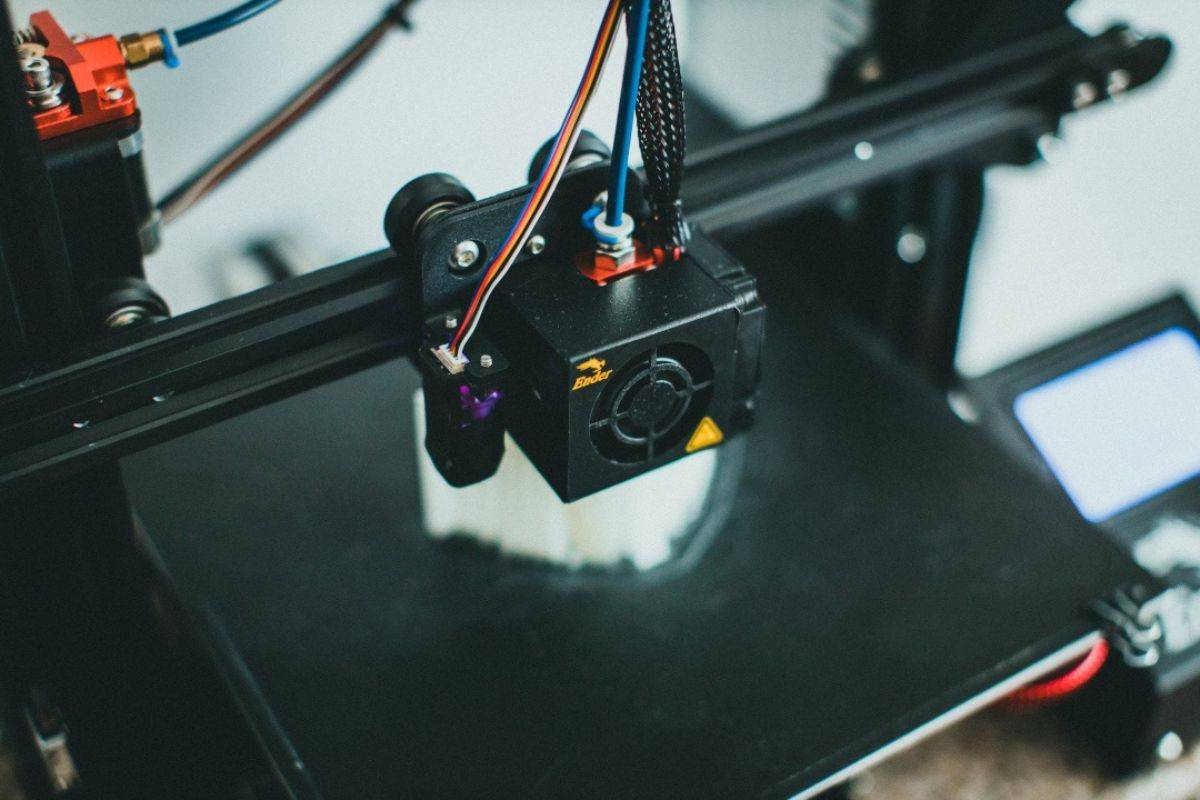

5. 3D printing and rapid prototyping

The integration of SolidWorks with 3D printing technologies has facilitated the rapid prototyping process, allowing designers to create physical prototypes of their 3D models in a matter of hours. This is especially useful for validating design concepts, performing functional testing, and presenting models to customers or investors before moving to mass production.

For example, a product designer might use SolidWorks to create a 3D model of a new device, 3D print a prototype, and test for ergonomics and functionality before finalising the design.

So, to develop your future as a product designer, you will need to master SolidWorks, an essential tool used in a wide variety of industries to create accurate models, perform simulations and optimise the development process. Its versatility and power allow designers and engineers to transform ideas into real products, ensuring they are efficient, functional and aesthetically appealing.

How to download Solidworks?

If you are interested in downloading this modelling software, it is best to visit the official website www.solidworks.com/es where you can easily find all SOLIDWORKS® products and the 3DEXPERIENCE® portfolio.

Check the different plans according to the use you are going to make of it. If you are a student, the best plan is the "Academy" plan, where you can acquire the universal design and engineering skills needed for a rewarding career path. This is the most comprehensive resource for teaching 3D mechanical CAD, design validation and data management.

UDIT: a unique advantage for students

Students of the Master in Product Design will have the opportunity to become certified as experts with Solidworks, both in the basic CSWA-Academic certification and in the advanced CSWP certification, highlighting their profile above the competition.

For one year, they will be trained in a discipline that combines art, science and strategy, developing projects in cutting-edge facilities that integrate the latest technologies and professional equipment such as a digital manufacturing and 3D printing laboratory.

More information

The transformation of industry through digital manufacturing