Sustainable PLA Aerogel-Based PCMs:

Enhanced Performance for Energy Storage and Thermal Management

Project information

- Project title: Flame-Retardant Aerogels for advanced Phase Change Materials.

Code: INC-UDIT-2025-PRO21

IP Project: Phd. Xiaomei Yang(xiaomei.yang@udit.es)

Objectives

Can We Create Fire-Safe and Sustainable Phase-Change Materials for a Greener Future?

- Design and develop new fire-safe phase-change materials: Realize a new generation of high performance PLA aerogel-based phase-change materials through structurally optimal aerogel encapsulation.

- Find, fabricate and optimise bio-based supporter materials for form-stable and fire safe PCMs.

- Provide a broader technical window and optimal solutions for the sustainable development and low-carbon life.

Methodology

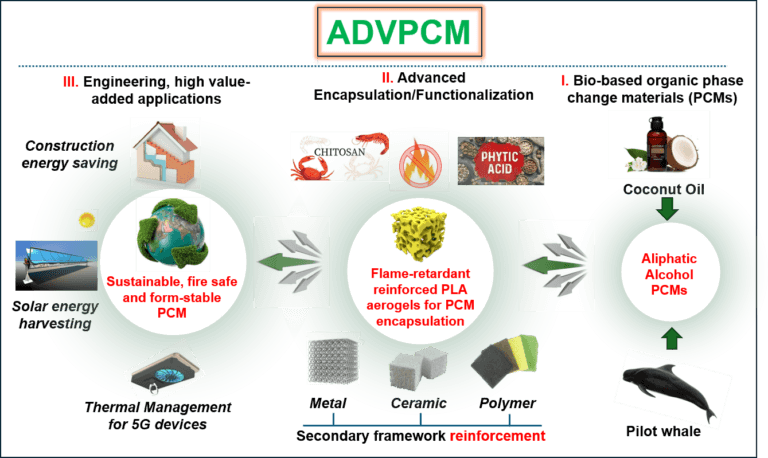

Our methodology focuses on developing fire-safe, bio-based phase-change materials (PCMs) through advanced aerogel encapsulation strategies to enhance thermal energy storage, mechanical stability, and flame retardancy.

We begin by selecting sustainable PCMs, prioritizing high latent heat, cost-effectiveness, and application-specific melting temperatures, with paraffin and PEG as model substances.

To improve fire safety and PCM retention, we explore multiple aerogel functionalization strategies, including chitosan/phytic acid (PA) coating and calcium alginate dip-coating. Additionally, we investigate a sodium alginate-assisted fabrication method to create inherently flame-retardant PLA aerogels and compare its efficiency with dip-coating techniques.

To ensure effective PCM encapsulation, we utilize vacuum impregnation technologies, allowing deep penetration of PCMs into the aerogel matrix for enhanced stability, leakage prevention, and improved phase change efficiency. Furthermore, we integrate metal, ceramic, and polymeric frameworks to reinforce aerogels, enhancing their mechanical strength while maintaining efficient thermal regulation. Across all approaches, we systematically evaluate PCM loading capacity, phase change performance, thermal stability, mechanical properties, and fire resistance using advanced characterization techniques.

This comprehensive methodology aims to develop next-generation, eco-friendly PCMs for applications in sustainable construction, thermal management, and energy-efficient materials.

Fig. Application example for the obtained PCMs products

Practical applications

This study demonstrates the practical applications of multifunctional, high-performance PCM composites, particularly PLA aerogel-based PCMs, in critical areas such as solar-thermal energy storage, electronic device thermal management, and energy-efficient buildings.

These composites enhance solar energy utilisation by addressing low conversion efficiency and diurnal fluctuations, thereby reducing electrical costs. In electronics, they prevent overheating, improving efficiency and prolonging the lifespan of components such as CPUs, GPUs, SSDs, and mobile devices.

In the construction sector, they contribute to energy savings by optimising heating and cooling while enhancing fire resistance, making them suitable for integration into foundations, walls, ceilings, and roofs. Ultimately, this work represents a key advancement toward the commercialization of PLA aerogel-based PCMs, unlocking their potential for sustainable energy harvesting, thermal regulation, and energy conservation.

Overview of objectives of ADVPCM: Step I, Bio-based organic phase change materials (PCMs); Step II, Advanced Encapsulation/Functionalization; Step III, illustration of three typical application cases.

innovation and competitiveness

This study introduces a highly innovative approach to PLA aerogel-based PCM composites, enhancing thermal regulation, fire safety, and structural stability while utilising biodegradable and fire-resistant materials as a sustainable alternative to conventional PCMs.

By addressing key challenges in energy storage, thermal management, and fire safety, these materials demonstrate superior thermal energy storage capacity, lightweight structure, and multifunctionality, making them highly competitive in solar-thermal energy storage, electronics cooling, and energy-efficient construction. Their scalability, cost-effectiveness, and compatibility with existing manufacturing processes further enhance their market viability, positioning them as an advanced, eco-friendly solution for industries focused on green energy and sustainable materials.

This innovation not only advances academic research but also strengthens the global competitiveness of biodegradable PCM technology, paving the way for its widespread adoption in next-generation thermal management and energy storage systems.