What is a digital twin and why is it transforming the industry?

In the most advanced industries and factories, concepts such as Big Data, Artificial Intelligence, the Internet of Things or Augmented Reality have long ceased to be technologies "to be adopted in the future", to transform the way in which production, operational efficiency and innovation are conceived in the present.

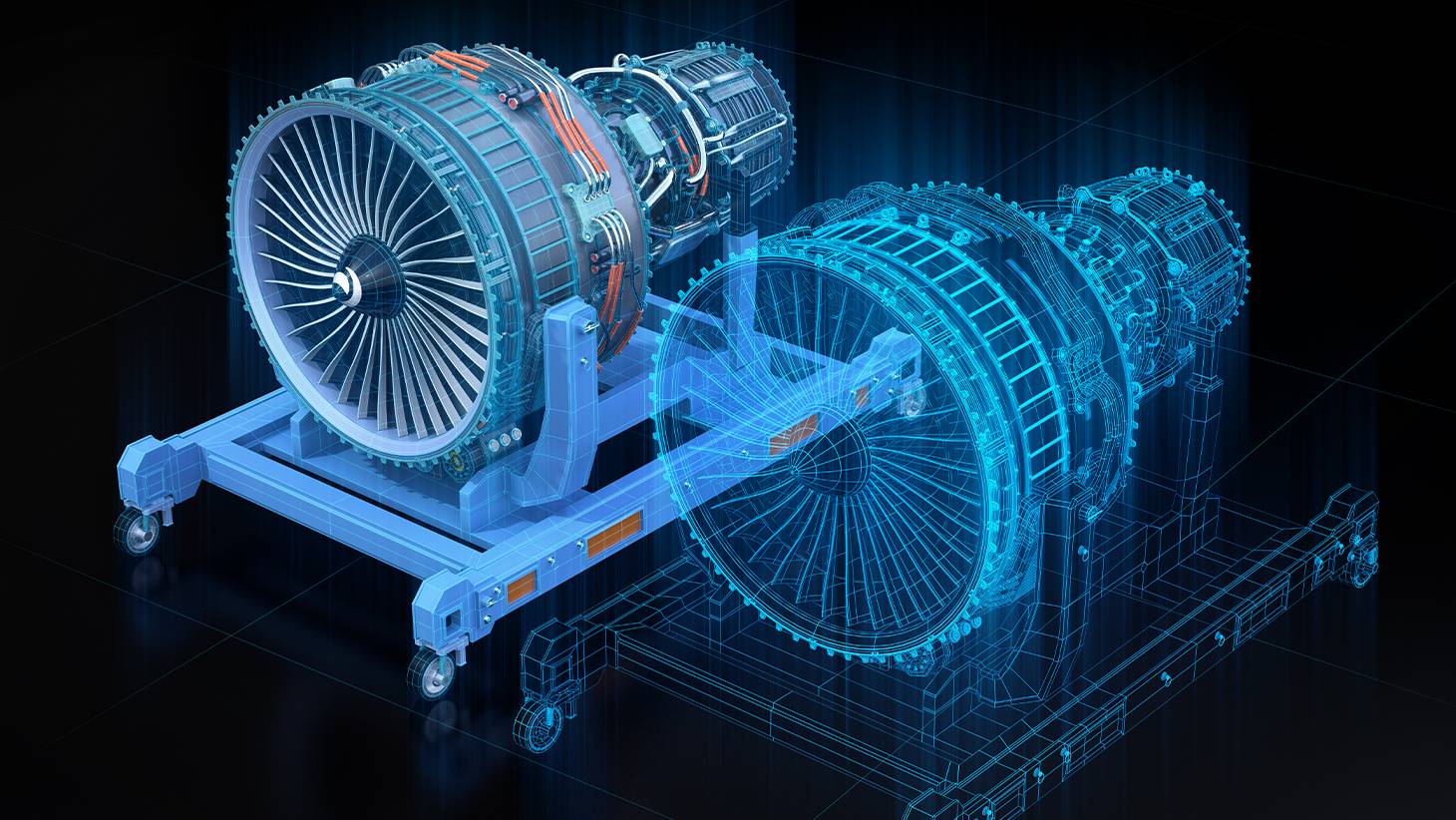

In this context, one technology stands out for its disruptive potential: digital twins, virtual replicas of physical objects, processes or systems that not only mimic, but also understand, analyse and predict their behaviour. Thanks to the constant collection of real-time data from sensors and connected devices, digital twins can anticipate failures, simulate all kinds of scenarios and propose solutions before problems occur.

Through the use of artificial intelligence algorithms, digital twins can also create predictive models that anticipate needs, optimise performance and enable real-time process adjustments. This agile responsiveness translates into continuous improvement in efficiency and decision-making. Moreover, in these virtual environments it is also possible to test new functionalities or designs before their physical implementation, which improves product quality, increases security and accelerates innovation cycles.

Finally, another key benefit of this technology is the reduction of costs and risks. Simulating processes or products in these environments makes it possible to anticipate and avoid errors that, in the physical world, could be very costly. This simulation and response capability has already made digital twins a strategic tool in all kinds of industries.

Creating a digital twin

The development of a digital twin begins with the creation of a virtual model of the object or system to be replicated. This model is built using 3D design, CAD or parametric modelling tools, depending on the complexity and level of detail required.

Sensors and IoT devices are then integrated into the physical object, collecting real-time data on key variables such as temperature, pressure, speed or operational status. This data is continuously sent to the digital model, which interprets it using algorithms. More advanced digital twins can also incorporate technologies such as augmented reality or 3D visualisation, offering users more interactive interfaces and improved decision-making. It is also important to note that this creation process never ends: as more data is accumulated and the physical system changes, the virtual model is updated, improving its fidelity and predictive capabilities.

In this field, students such as those on UDIT's Bachelor's Degree in 3D Animation, Games and Interactive Environments have a strategic opportunity to integrate themselves into this technological environment. Thanks to their specialised training in 3D modelling, immersive environments and programming, they are able to participate in the visual and functional design phase of digital twins.

Their mastery of tools such as graphics engines, virtual reality and interactive visualisation allows them to create realistic and operational digital representations that facilitate the understanding, simulation and control of complex systems in sectors such as industry, architecture, health or transport.